WAS-5000 Wide Band Acoustic Transducer: Full-range Noise Evaluation for Critical Aerospace Systems

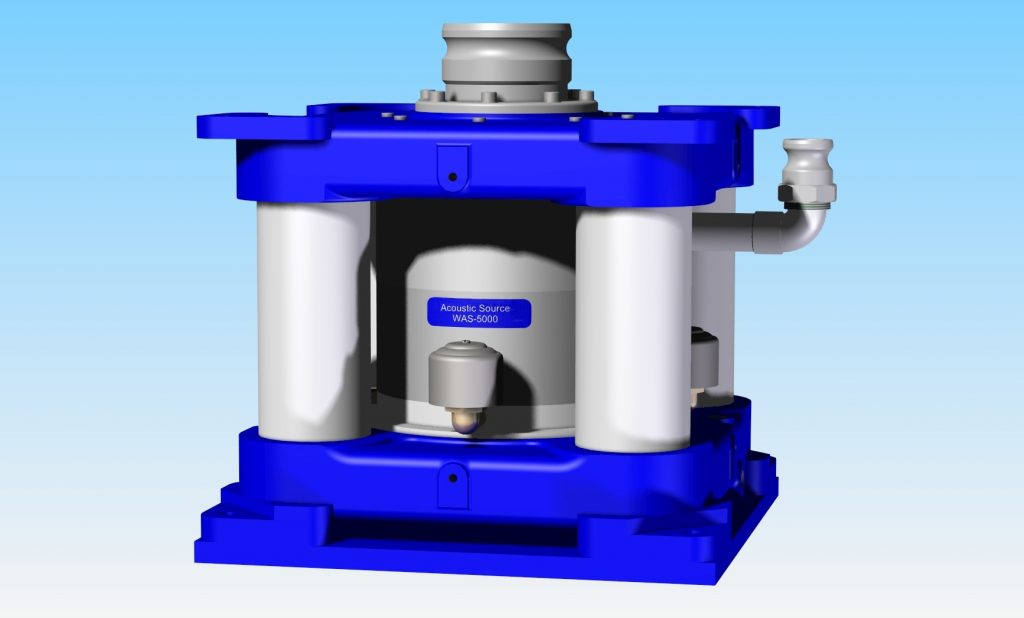

For comprehensive noise evaluation of large spacecraft, missile, or advanced aircraft system components, our WAS-5000 Wide Band Acoustic Transducer can handle it all. It applies the principle of vibrating vanes to reproduce exact sine wave, random noise, and sine-random combinations.

Primarily used in acoustic test chambers, the WAS-5000 is an electro-pneumatic noise source rated at 10 kW output over a frequency range of 25 to 5,000 Hz.

Essential Simulation Testing Applications, Covered

Will your aerospace vehicle withstand the vibration during launch and flight? GVIRL’ pre-flight structures and components qualification testing can give you the confidence and peace of mind that your vehicle will meet all reliability requirements.

Because pressure fluctuation over the external skin is the principal source of vibration in modern flight vehicles, acoustic energy offers a logical and effective simulation tool for reliability testing. GVIRL acoustic test facilities can simulate these external pressure fluctuations during vital structural and component testing. What’s more, our engineers can configure qualification tests to evaluate designs, gauge reliability, and provide total system checkout.

The WAS-5000: A Symphony of True Random Noise Input and Output

It all begins with a stable, reliable operational foundation. This transducer uses an inductive drive system acting on its reciprocating valve assembly.

The WAS-5000’s magnetic structure houses and supports two driver coils. It’s hollow conductor field coil is water-cooled, while the driver coils are cooled by air, water droplets, and vapor through an external cooling system. This high-efficiency cooling system produces the high currents required for high-frequency operation.

The driver coils, in conjunction with the field coil, are inductively coupled to the reciprocating valve’s single shorted turn. The modulation valve incorporates two concentric cylinders, each with rows of modulation slots. With air pressure applied outside of the reciprocating valve cylinder, air is forced through these slots.

Motion in the reciprocating valve increases and decreases the opening size of the modulation slots, based upon the polarity of the electrical input signal. This process breaks the air stream into “puffs,” which become pressure pulses at the discharge of the WAS-5000.

The key advantage of this reciprocating vane modulator is that a true random noise input produces a true random noise output, along with additional signals – such as discrete frequencies or sweeps – can be superimposed on the random noise.

This design allows the valve to achieve the extremely high acceleration levels necessary for operation at high frequencies.

WAS-5000 Characteristics

The WAS-5000 converts approximately 1500 scfm (42.5 m3/min.) at 30 psig (2 bars) of airflow into 10,000 acoustic watts, with a linear relationship of air flow to power output.

By Your Side With Full Service Support

Since 1949, GVIRL has been a specialized testing and simulation services partner to the Aerospace, Defense, and Commercial industries.

We save you precious time, # and money for short-term test requirements through GVIRL-owned and operated reverberant and progressive wave acoustic test facilities.

And should your needs be larger in scope, we will gladly accommodate you with turnkey acoustic facility development and engineering support. GVIRL is fully capable of taking on single-source responsibility for design, engineering, construction management, instrumentation and control systems, operation, maintenance, and personnel training.

Contact us today to learn the full specifications of the WAS-5000 and how GVIRL can help you upgrade your RATF.

Client Login

Client Login